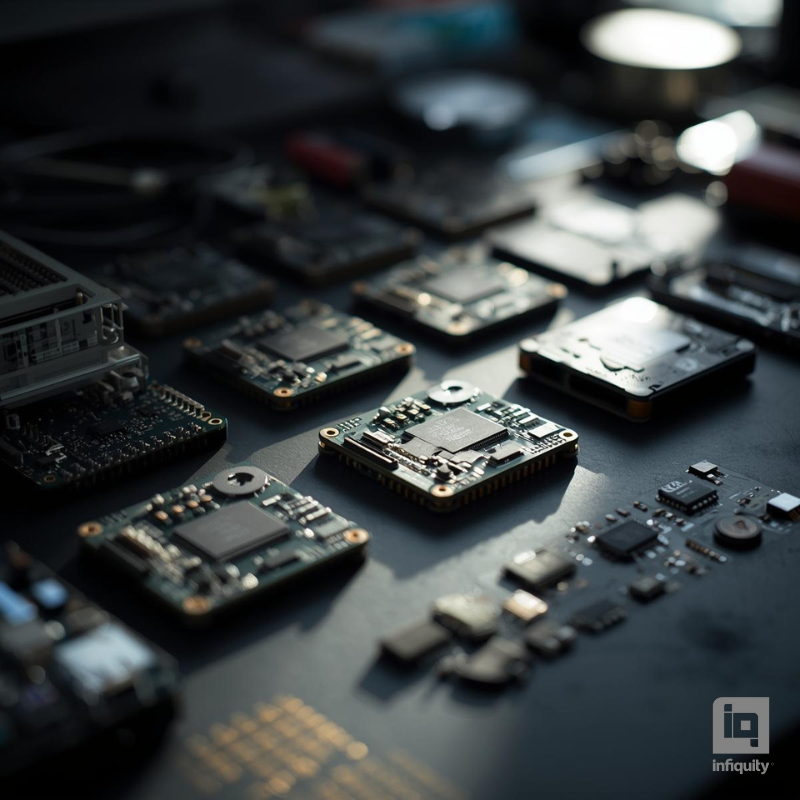

End-to-end electronics & embedded design

Electronics & Embedded Engineering

Infiquity provides comprehensive electronics and embedded engineering services supporting product development across automotive, industrial, and connected device domains. Our expertise spans PCB design, embedded systems, EMI/EMC readiness, homologation, and certification support—ensuring reliable, compliant, and production-ready products.

Our Electronics & Embedded Engineering Capabilities

1

PCB Design & Development

Complete PCB design services including schematic capture, layout, signal integrity, power design, BOM optimisation, prototyping, and production support for automotive and industrial electronics.

2

Embedded Systems Development

Firmware and software development for microcontrollers and processors, including bare-metal and RTOS-based systems, driver development, middleware integration, and system bring-up.

3

EMI / EMC Engineering

Pre-compliance design reviews, layout optimisation, shielding strategies, testing support, and issue resolution to ensure electromagnetic compatibility and regulatory readiness.

4

Homologation Support

End-to-end support for product homologation including documentation, test coordination, regulatory guidance, and liaison with test agencies for automotive and electronic products.

5

Certification Support

Assistance with AIS, BIS, CE, FCC, ISO and OEM-specific certification requirements, including technical documentation, test preparation, and audit support.

IQ Electronics & EMBEDDED Services

Engineering & Validation CAPABILITIES

We support electronics and embedded product development with structured engineering, validation, and compliance workflows that ensure design robustness, reliability, and production readiness.

-

Hardware design validation & bring-up support

-

Embedded firmware integration & debugging

-

Interface validation (CAN, LIN, SPI, I2C, Ethernet)

-

Signal integrity, power integrity & log analysis

-

Pre-compliance checks and issue resolution

-

Design verification & production readiness support

-

Improved design reliability

-

Reduced rework and validation effort

-

Faster compliance readiness

-

Smoother transition to production

Coverage Areas

Comprehensive coverage across hardware design, embedded software, compliance, and production readiness.

Hardware Architecture & Design

-

Schematics, component selection, power integrity, signal integrity, design reviews.

PCB Layout & Manufacturing Readiness

-

Multi-layer layouts, DFM/DFA, impedance control, thermal considerations.

Embedded Firmware & Software

-

Drivers, RTOS, middleware, bootloaders, diagnostics, communication stacks.

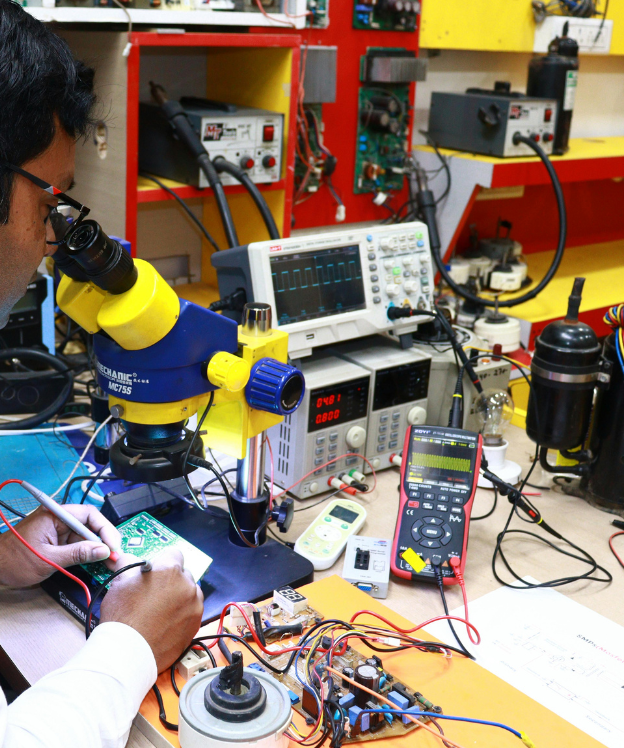

Validation, Debug & Bring-Up

-

Board bring-up, debugging, functional validation, stress testing.

EMI/EMC & Regulatory Compliance

-

Noise mitigation, grounding, shielding, pre-compliance testing.

Certification & Industrialisation Support

-

Documentation, audits, certification testing, production transition.

TOOLCHAIN & ENVIRONMENTS SUPPORTED

Design Tools:

Altium Designer, KiCad, OrCAD, LTspice, MATLAB

Embedded Platforms:

ARM Cortex-M/A, automotive MCUs, RTOS, Linux-based systems

Interfaces:

CAN, LIN, SPI, I2C, UART, Ethernet

ENGAGEMENT MODELS

-

Concept-to-prototype development

-

Design-only or build-to-spec support

-

Compliance & certification assistance

-

Production readiness & scale-up support

-

Dedicated engineering teams

Sample Test Scenarios

-

Board bring-up and power-on validation for new hardware

-

Interface validation across SPI, I²C, UART and Ethernet

-

Firmware integration and peripheral driver debugging

-

Signal integrity and power noise analysis during stress conditions

-

EMI issue identification and mitigation during pre-compliance

-

Functional validation before certification and production release

Why Choose Us?

-

Board bring-up and power-on validation for new hardware

-

Interface validation across SPI, I²C, UART and Ethernet

-

Firmware integration and peripheral driver debugging

-

Signal integrity and power noise analysis during stress conditions

-

EMI issue identification and mitigation during pre-compliance

-

Functional validation before certification and production release

Let’s Build the Future Together

Whether you’re developing an automotive platform, designing new electronics, or scaling digital systems — INFIQUITY brings the expertise to move faster.