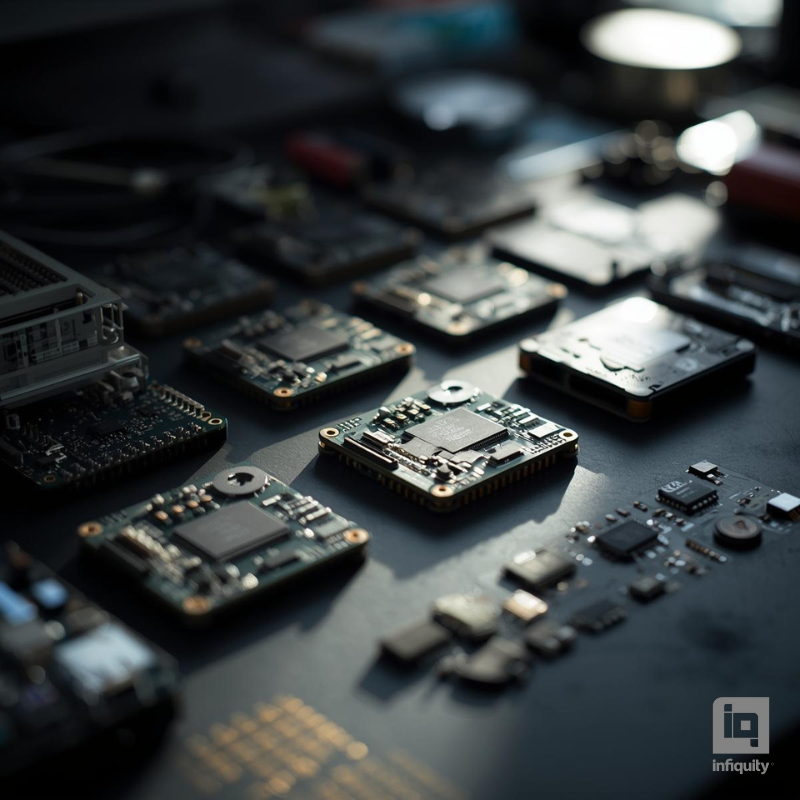

End-to-end product design services

Product Design

Infiquity provides comprehensive product design services supporting the complete journey from concept to production-ready products.

Our multidisciplinary teams combine electronics design, mechanical engineering, and system-level integration to deliver robust, manufacturable, and compliant products across industries.

We work with startups, OEMs, and enterprises to turn ideas into reliable, scalable products.

Our Product Design Capabilities

1

Electronics Product Design

2

Mechanical Product Design

Mechanical engineering and enclosure design focused on functionality, reliability, and manufacturability.

Coverage includes:

-

Industrial design support

-

Enclosure and housing design

-

Thermal and structural analysis

-

Material selection and tolerance analysis

-

DFM/DFA considerations

3

End-to-End Product Development

Integrated product development bringing electronics and mechanics together into a complete system.

Coverage includes:

-

Requirement definition and feasibility analysis

-

Cross-domain system integration

-

Prototype build and testing

-

Compliance and certification readiness

-

Production handover and scale-up support

IQ Product Design Services

Product Design CAPABILITIES

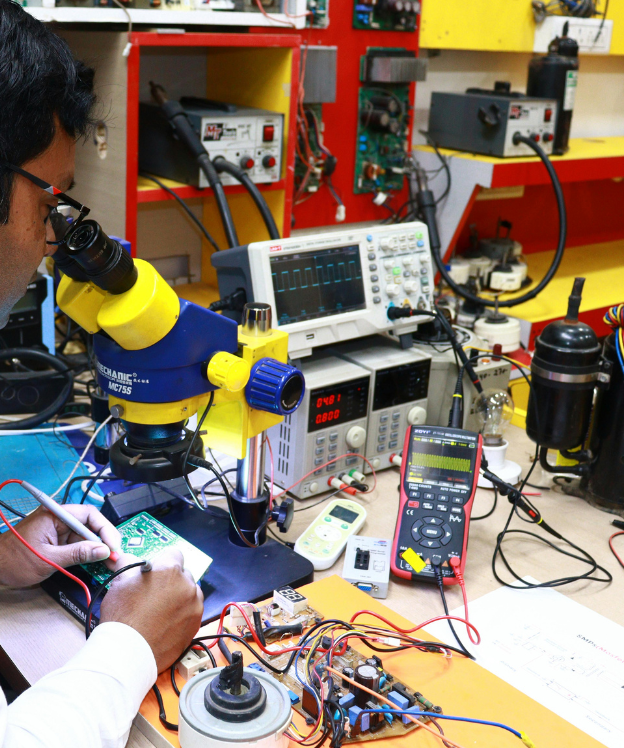

We provide structured product engineering and validation capabilities that bridge concept design and production readiness. Our approach combines electronics, mechanical engineering, and system-level validation to ensure products are robust, manufacturable, and compliant from day one.

-

Electronics design validation and prototype bring-up

-

Mechanical fitment, enclosure validation, and tolerance checks

-

Embedded firmware integration and functional validation

-

Cross-domain system integration (electronics + mechanics)

-

Design verification through testing and iteration

-

Pre-production validation and readiness assessment

-

Robust and manufacturable product designs

-

Reduced design rework and late-stage changes

-

Faster validation and iteration cycles

-

Smoother transition from prototype to production

Coverage Areas

Comprehensive coverage across concept, design, validation, and production readiness.

Concept & Requirement Definition

-

Product ideation, feasibility analysis, requirement capture, and architecture planning.

System Architecture & Integration

-

Definition of system-level architecture integrating electronics, mechanics, and software.

Detailed Design & Engineering

-

Detailed hardware, firmware, and mechanical design with design reviews and optimisation.

Prototyping & Validation

-

Prototype builds, functional validation, testing, and design iteration.

Compliance & Certification Readiness

-

Design alignment with regulatory requirements, documentation, and test preparation.

Manufacturing & Scale-Up Support

-

Design for manufacturability, production transition, and vendor coordination.

TOOLCHAIN & ENVIRONMENTS SUPPORTED

Electronics & Embedded:

Altium, KiCad, OrCAD, ARM-based platforms, RTOS

Mechanical Design:

CAD / CAE / CAM foe design, thermal & structural simulation tools

Prototyping & Manufacturing:

Rapid prototyping, PCB assembly, enclosure fabrication

ENGAGEMENT MODELS

-

Concept-to-production product development

-

Design-only or build-to-spec engagement

-

Rapid prototyping and validation

-

Dedicated product engineering teams

-

Dedicated engineering teams

Sample Test Scenarios

-

Design of a connected electronic device from concept to pilot production

-

Electronics and enclosure redesign for thermal and cost optimisation

-

Rapid prototype development for proof-of-concept validation

-

Product certification support for regulatory approval

Why Choose Us?

-

Multidisciplinary teams covering electronics, mechanics, and systems

-

Strong focus on manufacturability and compliance

-

Practical engineering approach from concept to production

-

Flexible engagement models aligned to product maturity

Let’s Build the Future Together

Whether you’re developing an automotive platform, designing new electronics, or scaling digital systems — INFIQUITY brings the expertise to move faster.